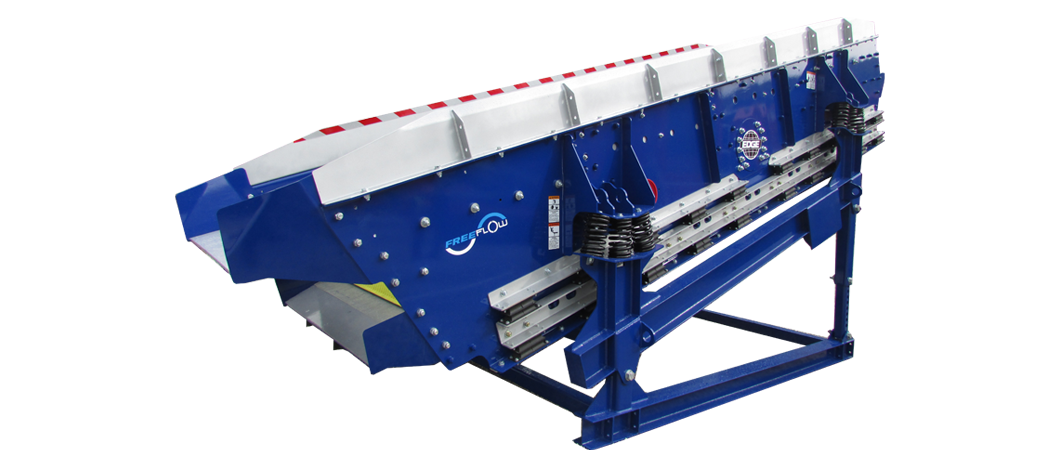

With mat acceleration rates of up to 50g, the award winning EDGE FreeFlow screener is the most aggressive flip flow screen on the market. The EDGE FreeFlow screener range provides a highly efficient screening solution for sticky, moist materials with a high percentage of fines and is ideal for the processing of compost, wood, skip waste, trommel fines, construction and demolition waste and incinerator ash. Designed to eliminate the blinding or blockage of screen media that often occurs with traditional screening machinery when screening wet or sticky material, the EDGE FreeFlow screen ensures maximum uptime and superior screening results.

The EDGE FreeFlow Screener range allows for two screening operations in one unit. Customers can now process non-prescreened material via the FreeFlow’s robust scalping screen top deck whilst providing a fine screening function of difficult to screen material via the flip flow bottom deck. This allows for large unscreened material to be screened on a flip flow screen.

With increased throughput, high efficiency, adjustable speed and throw and quality end products; the EDGE FreeFlow Screen range is the ideal separation solution for difficult to screen materials.

FreeFlow 186 Flip Flow Features

- Most aggressive flip-flow screen on the market with mat acceleration of up to 50g

- Intelligent modular top deck system allowing numerous media types to be quickly and easily installed side by side

- Combines a unique stepped top deck with innovative flip flow bottom deck technology

- Eliminates screen plugging and blockages

- Bolt free modular bottom deck media enables for a quick exchange procedure

- Top deck screen media can be quickly and easily replaced thanks to their modular design

- Dead areas at feed shelf and top deck cross members have been reduced to maximise screening area

- Ability to run 10% faster than competing flip flow screens

Applications

- Construction and Demolition Waste

- Domestic and Household Waste

- Glass Fines

- Incinerator Waste

- Mulch / Organics

- Municipal Solid Waste

- Shredder Waste

- Wood

Options

- Power-source: Hydraulic / Direct Electric

- 3D Screen media

- Punch Plate or Rubber media

- Woven Mesh media

- Bofor Bar media

- Finger Deck media

- Air Knife

- Dust Extraction system

English

English German

German Distributor

Distributor

Brochure

Brochure

Quote

Quote

Social

Social

Careers

Careers